Engineering for Beginners: How Air Compressors Work

Take a deep breath, the deepest breath you can. Now hold it for a moment.

Now blow that breath of air out as hard as you possibly can! For your next task, place a nail on a piece of wood, take the same deep breath and blow it out with enough force to drive that nail into the wood.

Of course, this isn’t possible for you to do, but with the modern marvel of air compressors, it can be done and with less air than it would take to inflate a balloon. How is this accomplished?

You certainly know what an air compressor does but perhaps not how air compressors work. So here you are, to learn the quick and dirty on the light and airy.

Where are Air Compressors Used

First of all, where are air compressors found? Air compressors are everywhere, drive to a gas station, a mechanic or just about any factory, and there it is, running tools, powering machines, making brakes work, and even cooling the air in your home or car.

They can even be used to apply certain types of makeup for a smooth, decorative finish that will withstand a hurricane. However, please don’t go stand out in a hurricane.

In the past, just like computers, air compressors were giant machines that took up entire rooms in factories and were too expensive for the average person to own.

How Air Compressors Work

Most air compressors do exactly that, they compress air. As air is pressurized its volume decreases and it is then stored for later use. The best example of what is happening comes from soda or pop bottles.

The next time you go to open one, feel how sturdy and solid the bottle is before and right after you open it. Feel how much softer the bottle is after the extra gas hisses out.

Many common compressors use a piston and cylinder like the one found in a car’s engine, although there are models which use screws or encased propellers. Piston driven compressors tend to be very loud because the piston is first drawing air in and then punching it into a discharge tube which leads to a large tank.

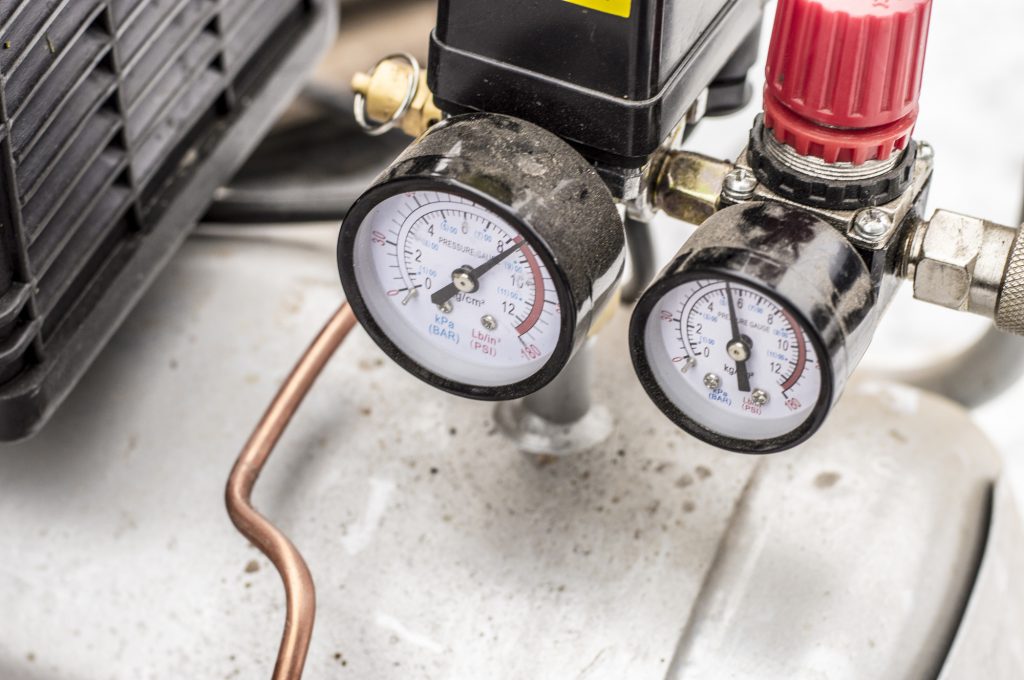

More and more air is added to the tank by systems of valves until it reaches the cutoff point established by a regulator, usually no more than 125 psi. Most compressors of this type have oil for lubrication which can get into the compressor and come out with the air, which can be a cause for concern.

Also, because it is taking atmospheric air in, water can be a concern as well and you must drain it from the tank periodically.

Why Not Learn More

So there you have it, you now know the basics of how air compressors work. You are probably already thinking of DIY projects you could accomplish with greater efficiency by using an air compressor. And that means less time on the Honey-do list and more time with a cold beverage in your hand.

Think of it, painting the house, easily running tools, inflating tires in your own garage, the only real limit to the use of air compressors is your own imagination.